Diaphragm Seals & Capillaries

A direct connection or capillary is used to connect the measuring instrument to the diaphragm seal. Capillaries are helpful for remotely mounting instruments. Fortunately, to help you find the best diaphragm seals and capillaries for your applications, Haygor supplies a broad range of options from the top manufacturers in the world.

Build your diaphragm seal here.

WHY USE DIAPHRAGM SEAL SYSTEMS?

In short, diaphragm seal systems offer protection to guarantee reliability and safety. They protect gauges from contaminated, hot, corrosive, or viscous materials. To prevent gauge failure that can cause safety problems for personnel and operations, diaphragm seals offer an added layer of protection to make sure the media does not reach the gauge.

Diaphragm seals also extend the service life of the pressure instrument, which reduces process downtimes. They prevent corrosion, contamination, or clogging of your pressure gauges while eliminating or reducing maintenance costs. Plus, they reduce fugitive emissions.

WHAT ARE DIAPHRAGM SEALS MADE OF?

Diaphragms seals are available to handle a broad range of applications and fluids. Elastomers are commonly used, since diaphragm seals must be highly flexible. They also include a vast array of both specialty and general purpose rubbers. Low pressure applications generally benefit from the use of elastomers.

When specific chemical compatibility and high pressure ratings are required, metal diaphragms made of titanium, stainless steel, or various other metals are used. Flush welded versions and flanged assemblies are available.

WHEN ARE DIAPHRAGM SEALS USED?

Whenever a process fluid needs to be protected from a pressure sensor, or vice versa, a diaphragm seal will come in handy. For instance, in pharmaceutical and food sanitary processes where allowing process fluid to accumulate could compromise the purity of the fluid. Or, if the metal surface of the pressure sensor could contaminate a very pure process fluid, as in the petrochemical industry, diaphragm seals and capillaries should be utilized.

|

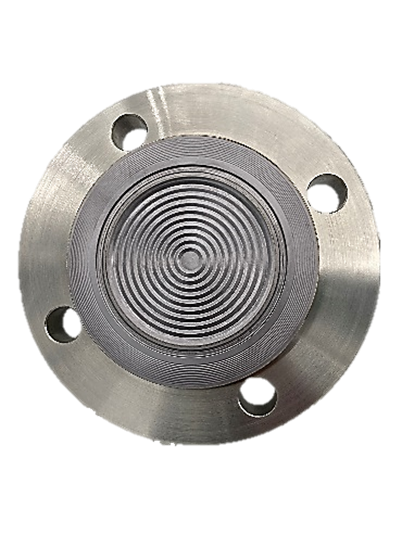

FLUSH FLANGED DIAPHRAGM SEAL

|

|

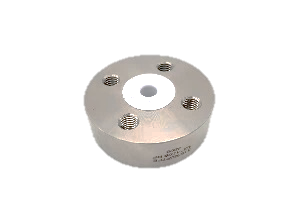

FLANGED PANCAKE DIAPHRAGM SEAL

|

|

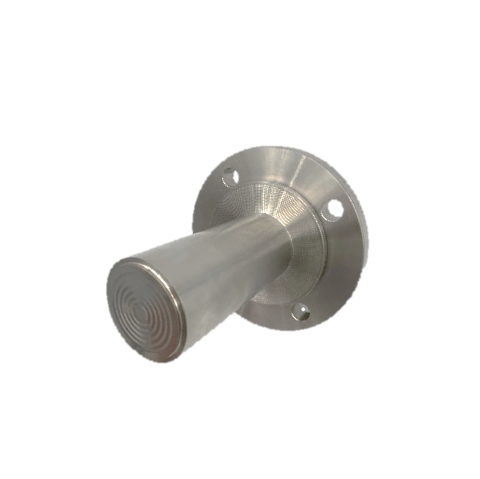

FLANGED EXTENDED DIAPHRAGM SEAL

|

|

FLANGED OFFLINE DIAPHRAGM SEAL

|

|

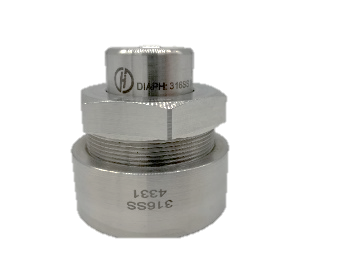

THREADED OFFLINE DIAPHRAGM SEAL

|

|

ALL WELDED THREADED MINI DIAPHRAGM SEAL

|

|

SADDLE DIAPHRAGM SEAL

|

|

FLUSH THREADED DIAPHRAGM SEAL

|

|

CHEMICAL TEE / WEDGE DIAPHRAGM SEAL

|

|

PULP & PAPER DIAPHRAGM SEAL

|